IV. Gas industry of Turkmenistan: from the past to the present

12:24 12.08.2024 25156

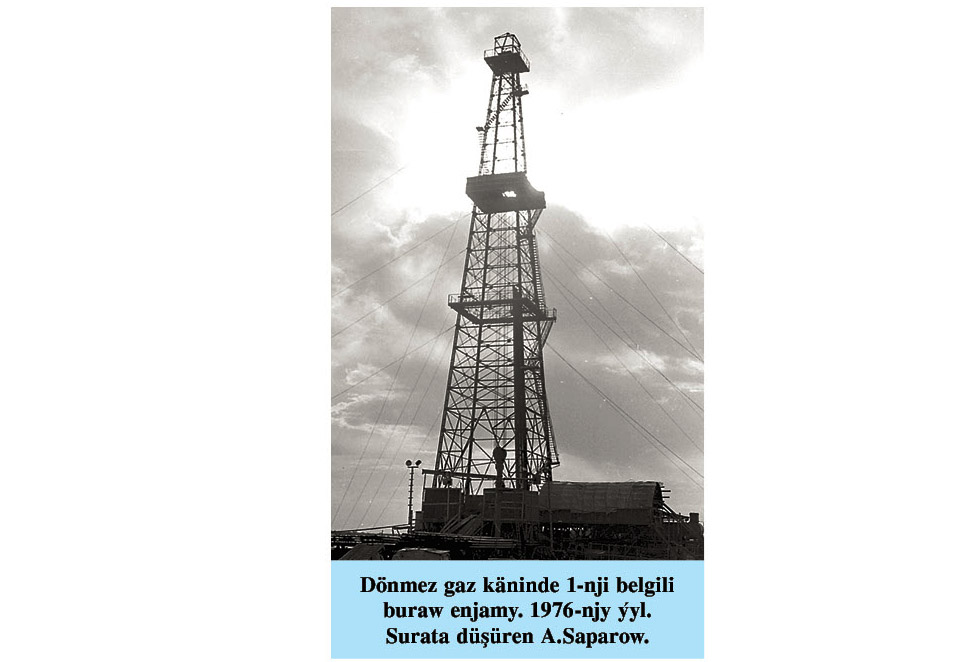

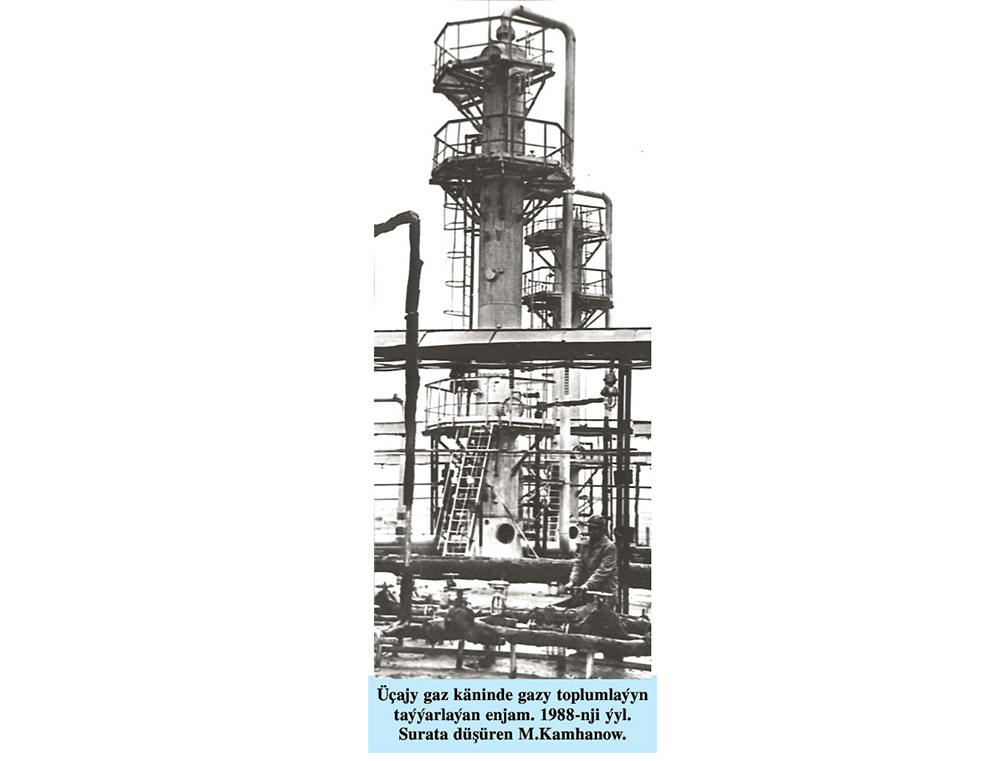

When the high efficiency of larger construction and installation work was proven at the Şatlyk gas condensate field, this method was also used at the Döwletabat-Donmez gas condensate field, which is one of the largest gas fields in terms of resources, as a result of which the field development time was reduced almost twofold, which certainly influenced the national economy. This production method was also used at the Üçajy, Seýrap, Malaý, 10 Years of Independence, Ýolguýi and other gas and gas condensate fields prepared for development.

The Döwletabat gas condensate field was discovered in January 1974 with the receipt of industrially significant gas inflow as a result of experimental work from the measuring (parametric) well No. 1 at a depth of 2,292 meters. The structure of this field was revealed as a result of seismic exploration studies conducted in 1969–1971. The gas field tectonically belongs to the Gummezli- Döwletabat hemi-anticline and the Badhyz-Garabil monoclinal fold.

To prepare the field for industrial exploitation, exploratory wells were drilled and deposits of the Neogene-Quaternary, Paleogene, Cretaceous, Upper Jurassic and Permian-Triassic periods were discovered.

The Döwletabat-Donmez field conditionally consists of three geologically related parts: Döwletabat-1, Döwletabat-2 and Döwletabat-3. These deposits were put into operation in 1982, 1984 and 1988, respectively, with wells placed according to the block system.

The Döwletabat-Donmez gas condensate field is located in the south-eastern part of Turkmenistan in the territory of the Sarahs etrap of the Ahal velayat and the Yoloten etrap of the Mary velayat. The city of Sarahs is located in the north-west of the field, with which it is connected by an asphalt road 18 kilometers. The nearest large settlement, the town of Tejen, is located 125 km in the north-west of the field, 100 km north of the city is the Şatlyk field, 50 km to the north-east is the Galkynyş field and 40 km to the south-east is the Gurrukbil gas condensate field.

In terms of orography, the region includes the north-western part of the Badhyz elevation, the eastern part of the Kopetdag Mountains and part of the hilly upland that turns into the Karakum Plain.

The relief of the region mainly consists of flat areas; in the south of the field, there are hills with a height difference of 100 meters, and in the north-east, there are rows of sand dunes.

In the southeastern part of this area, there are low ridges of Garanymbaýyr and Kesikburun and the Gummezli, Hangyry and Adjarly elevations of +475 +653 meters, which stand out among other elevations. In the north-west, in the area of the Hor-Hor reservoir, the terrain is somewhat leveled.

The field is distinguished by the complexity of the geological section of the developed productive layer (bed).

Part of the Döwletabat-1 field is located in the sulfur-free zone and contains gas condensate. There are three process units operating there, the capacity of each is 5 million cubic meters a day. Gas from Döwletabat -1 from the PGTU (preliminary gas treatment unit) is fed to the gas compressor unit (GCU), located in the Döwletabat-2 part. Then the gas is sent to the BCU-2 (booster compressor unit) inlet, where it undergoes complete purification and drying.

There are four PGTUs (Nos. 2, 3, 5 and 8) operating at Döwletabat-2. According to the design, the throughput capacity of each of them is 5 billion cubic meters a year. Their total capacity is 20 billion cubic meters of gas a year.

There are four PGTUs (Nos. 1, 4, 7 and 9) operating at Döwletabat-3. According to the design, the capacity of each of them is 5 billion cubic meters, in total – 20 billion a year. Main unit No. 2 with a design capacity of 20 billion cubic meters of tank gas a year is located in the sulfur part of the Döwletabat gas condensate field. Main unit No. 2 of the Döwletabat-3 unit purifies gas from PGTUs Nos. 1, 4, 7 and 9 and from the Gurrukbil field. A total of four desulphurization units are in operation.

Oraznazar HESHDEKOV

From the history of oil production in Turkmenistan

The first mention of oil in Turkmenistan, more precisely on the eastern shore of the Caspian Sea, dates back to the 18th century. There is evidence that in 1782, 20 oil wells were used on Cheleken (popularly called “oil island”), from which up to 4,000 poods of oil a year were extracted. The oil was shipped in wineskins (bags made of animal skin) by boats – prototypes of modern tankers.

IOGU Students at Work Practice

Students of Yagshygeldi Kakayev International Oil and Gas University underwent practical training in the directorates and trusts of the oil and gas industry. The production process established at modern enterprises of the country’s fuel and energy complex with the introduction of high innovative technologies contributed to the practical assimilation of theoretical knowledge by them.

No breakdowns to water supply to gas workers

A significant contribution to the work on the extraction of “blue fuel” from gas fields of one of the largest production units of the Türkmengaz State Concern – the Marygazçykaryş Directorate, and on its uninterrupted delivery to consumers is made by employees of the relevant organizations of the enterprise’s service system.

Balkan Hydrogeologists Replenish Drinking Water Supplies

The labor collectives of the Türkmennebit State Concern, which is one of the major production structures of the national economy of our country, which is marked by achievements, are confidently moving forward in the year “The Era of the People with Arkadag” to new heights of development.

The Number of Users of “Blue Fuel” in the Lebap Velayat Is Growing

Having directed the benefits of the country’s invaluable wealth – natural gas – to the rapid development of the Motherland and the wellbeing of his people, the President is successfully implementing a policy aimed at socioeconomic growth in Turkmenistan. The friendly team of the Lebapgazüpjünçilik Directorate of the Türkmengazüpjünçilik Association of the Türkmengaz State Concern also makes a worthy contribution to this matter of national importance. They work tirelessly to ensure the uninterrupted supply of natural gas to consumers.