Methods of obtaining hydrogen and the possibilities of its use

07:41 08.07.2025 1957

Currently, 85 percent of the world’s hydrogen is produced using steam methane reforming technology, 10 percent from oil and coal, and only 5 percent from water using electrolysis.

Within the framework of the Paris Agreement on reducing carbon emissions into the atmosphere, especially greenhouse gases and CO2, world experts have reached an agreement on a phased transition from carbon compounds: coal, natural gas and other fuels to environmentally friendly hydrogen energy. In particular, due to the growing demand in the world for low-carbon energy and the transition to hydrogen fuel, a change in the structure of demand for energy resources in the world market is expected in the future.

Diverse work is being carried out in Turkmenistan to develop international cooperation in the field of hydrogen energy, to study the experience of leading foreign scientific centers and companies, to collect and analyze data.

Hydrogen does have a number of advantages over methane as a fuel, although it has its drawbacks. Hydrogen is 8 times lighter than methane, has a higher heat capacity (7 times) and thermal conductivity (54 times), and a higher heat of combustion by 2.5 MJ/kg. In other words, when burning 1 kilogram of hydrogen to obtain the same amount of heat, it is necessary to burn 2.5 kilograms of methane.

The huge resources of natural gas in Turkmenistan indicate that our country has a potential to contribute to the development of hydrogen energy in the future.

There are several thermal and catalytic methods for producing hydrogen in laboratory and industrial conditions, including:

Method 1 – steam reforming of water. One of the main and most common methods is the production of hydrogen at high temperatures based on the conversion of natural gas into water vapor. This method releases a large amount of CO2, which is not emitted into the atmosphere, but is processed in agriculture in the technology of producing urea fertilizers. For example, currently, the production of ammonia at the Tejen, Mary and Garabogaz urea plants requires the use of large amounts of hydrogen. This process occurs at high temperatures (420 °C) and high pressures (28 MPa) with the participation of a catalyst. Currently, it is considered more environmentally friendly and technically and economically advantageous to separate hydrogen from methane and reuse CO2 as an intermediate product.

Method 2 – water electrolysis. This method requires a large amount of electricity and electrolysis equipment. To obtain electricity, a large amount of fuel energy and investments are required, and its cost increases.

Method 3 – salt water is cooled to -30 °C, then activated oxide MgO2 or Al2O3 is added, releasing pure H2. In this case, 1 kilogram of hydrogen is released per 1 kilogram of magnesium oxide. The disadvantage of this method is the problem of cooling salt water to low temperatures, but this method can be effective in countries with a cold climate (Antarctica).

Method 4 – catalytic reforming and thermal pyrolysis. In this method, methane reacts with water vapor or oxygen at high temperatures in the presence of a catalyst, forming synthesis gas (a mixture of H2 and CO), and then methanol (example – Ahal gasoline plant).

Method 5 – thermal pyrolysis – when cracking ethane at high temperatures (850 °C), ethylene is formed and hydrogen is released (example – Kiyanly Polymer Plant (KPP)).

In addition, in world practice, there are several methods for producing hydrogen, namely from biomass and algae and by chemical reaction of water with metals.

Arslanmyrat SOLTANNAYEV,

Head at the Laboratory of the Natural Gas Research Institute of the Türkmengaz State Concern

Deposits of drinking water with an area of 130.8 square kilometers were discovered in Lebap region

Deposits of drinking water with a total area of 130.8 square kilometers were discovered as a result of work carried out by specialists of the State Corporation «Turkmengeology» in Lebap region. This was reported by Vice-Chairman of the Cabinet of Ministers Shahym Abdrakhmanov at a government meeting last Friday.

The President of Turkmenistan and the Governor of St. Petersburg discussed cooperation issues

On December 25, the President of Turkmenistan Serdar Berdimuhamedov and the Governor of St. Petersburg Alexander Beglov discussed economic and cultural cooperation between St. Petersburg and Turkmenistan during a brief conversation.

President of Turkmenistan took part in informal CIS Heads of State Summit

President Serdar Berdimuhamedov left for a working visit to the Russian Federation on December 25 to take part in the informal CIS Heads of State Summit, traditionally held on the eve of the New Year, TDH reports.

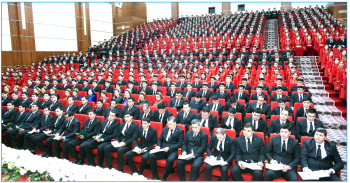

Presentation of Arkadag's book «Hakyda göwheri» was held at IOGU

A presentation ceremony of the new work of the National Leader of the Turkmen people, Chairman of the Halk Maslakhaty of Turkmenistan Gurbanguly Berdimuhamedov «Hakyda göwheri» was held at the International Oil and Gas University named after Yagshygeldi Kakayev.

Diesel fuel and jet fuel sold to Afghanistan at the auction

38 transactions were registered at the auctions of the State Commodity and Raw Materials Exchange of Turkmenistan last week.